- Details

- Category: Blog

- Hits: 5327

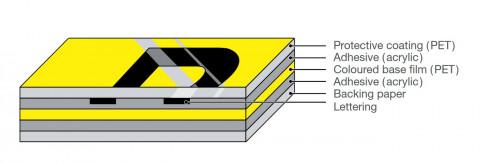

One drawback of the DK thermal papers used by the Brother QL series label printers currently supported by the etracer software is the printout fades over time. On the contrary the Tze series laminated tapes used by the Brother PT series label printers are advertised as very durable against water, chemical and extreme temperature. The Tze tapes are ideal for labeling vacuum tubes which can be hot when working in the application circuits. A detailed durability test data published by Brother can be found here: Durability test data for Brother laminated Tze labels

Structure of the Brother Tze laminated tape. Excerpted from the Brother brochure mentioned above

- Details

- Category: Blog

- Hits: 4303

At room temperature the filament of a tube has a much lower resistance compared to the resistance when the filament is heated completely by the rated heater voltage. When a tube is plugged into the etracer, by Ohm's law V=IR, the low resistance of the filament will conduct more current at the rated voltage and hence more power is dissipated on the filament during this period. The difference between the cold filament and hot filament resistances can be as high as 3 to 5 times and hence there is a worry that the power surge might damage the valuable tube. Although all tubes are designed to withstand this type of power surge it is desired by many people to minimize it's impact.

Read more: New heater supply soft-start feature added to the etracer PC control software

- Details

- Category: Blog

- Hits: 7137

Introduction

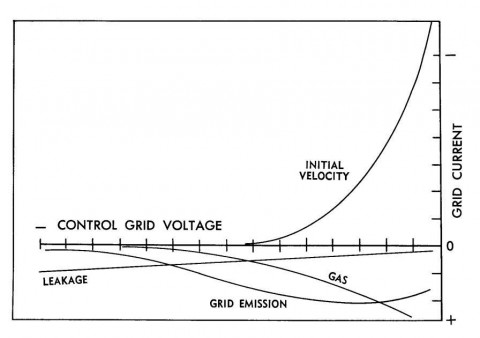

Gas test can be often found in traditional tube testers like a TV-7. The assumption for gas test is for a gassy tube there exists a non-zero grid current due to a leakage path between electrodes (plate, cathode and grid) under negative grid bias. The more the amount of gas inside the DUT the higher the grid current. However, according to [1] the grid current is a sum of at least four types of currents and leakage due to gas is only one source of it. Figure 1 is excerpted from [1] showing the four sources of grid current. By observing figure 1 we can see even the direction of the grid current is not necessary fixed.

Figure 1. Sources of grid currents

Nonetheless it might be desired to add the “gas test” function to etracer as it might reveal some interesting behaviors of the DUT against different resistances in the grid bias circuit.

- Details

- Category: Blog

- Hits: 5098

Introduction

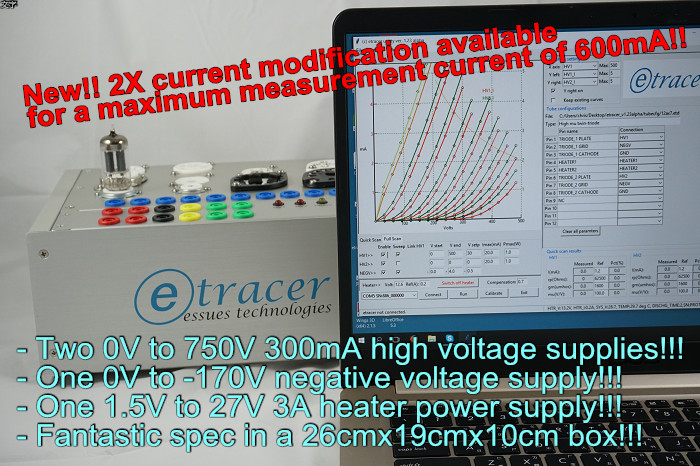

When designing a vacuum tube tester there are many factors to consider: the maximum test voltage, the maximum plate current, the range of the negative supply for the grid and the voltage/current rating for the heater to name a few. There are always trade-offs between cost and performance. Here we focus on the high voltage aspect. For an operating voltage as high as 800V DC in etracer the components need to be carefully selected to guarantee a maintenance -free operation for a very long period of time. And like an old saying “Quality doesn’t come cheap” components that are designed for higher voltage applications tend to be bulkier and pricier compared to their lower-voltage counterparts. It is found that several tube testers products and kits in the market have poor components selections. They are attractive at first glance because of the cheaper price tag but they might not last long and they might cause severe damage to the device or incur safety issues if something went wrong.

Read more: Considerations of components selection for etracer

- Details

- Category: Blog

- Hits: 7332

Introduction

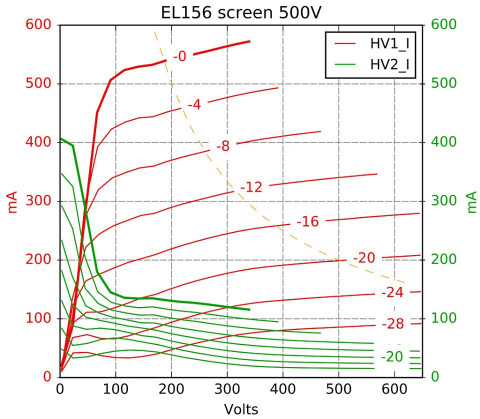

The maximum current measurement capability of etracer is designed to be 300mA. This capability is more than adequate for testing and tracing most of common audio tubes such as 300B, KT88 and 6550. However, it might be desired to have a higher current measurement capability for testing tubes like 6C33C or KT150. This application note describes the modification method needed to increase the current measurement capability to 600mA. Below figure shows a traced curves set with a Telefunken EL156 with a screen voltage of 500V!! under pentode connection. Please note the maximum plate dissipation is set to 100W to allow traces in the high current region.

Traces of a Telefunken EL156 under pentode configuration with a screen voltage of 500V

Page 1 of 3