I am not sure since when vacuum tube testers like etracer are categorized as "pulse-type" tube testers. And this type of tube testers are usually being criticized as not accurate because the DUTs are not biased at the quiescent point and hence during testing the temperature of the DUT is lower than the temperature of the DUT in the real circuits. However, little information can be found on the accuracy requirement. How bad is it? And how much deviation is acceptable? 1%? 10%. In this article I will explore this issue a little deeper and measurement data are provided for references.

First of all, we need a clear definition of a "pulse-type" vacuum tester: Only the heater in the DUT is powered to allow the cathode to emit free electrons before measurement. During measurement time (pulses) the plate and the grid electrodes of the DUT are connected to voltage supplies and the current flowing through the DUT is measured during this time period. The measurement pulses are usually very short (500uS to 5mS in etracer) and are controlled by a micro-controller. With this definition, it is interesting that many of the traditional tube testers like Hickok TV-7 or Hickok 539x are all pulse-type testers. These testers supply heater voltage to the DUT during idle time. The test voltages for the grid and plate are only connected to the DUT when a button is pushed or a level is pulled to display the reading on the meter. The only difference between these old testers and testers like etracer is that the measurement pulses on the old testers are provided manually by the operator. If the impact of the bias point is significant the operator should observe a rapid-change in the reading when the test button is depressed.

Secondly, let's assume for a while that the glass temperature does significantly affect the result of the measurement. A question naturally arise: what quiescent point (and hence glass temperature) should we set for conducting the test? Is a point close to the maximum plate dissipation always the best choice? There are virtually unlimited choices for quiescent point for a vacuum tube. And usually the operation point changes when the vacuum tube is aged. Taking the output stage of a power amplifier for example. There are roughly three choices of quiescent point: class A, class AB and class B. Among the three types only class A is biased close to the DUT's maximum plate dissipation. The bias point for both class AB and class B are usually below the maximum plate dissipation. There are also tubes designed for class C or pulsive (computer) applications. What bias points should we use for these type of tubes? If the impact from the choice of quiescent point is so big why didn't the tube manufacturers provide many test curves sets and designate each set for a specific quiescent point?

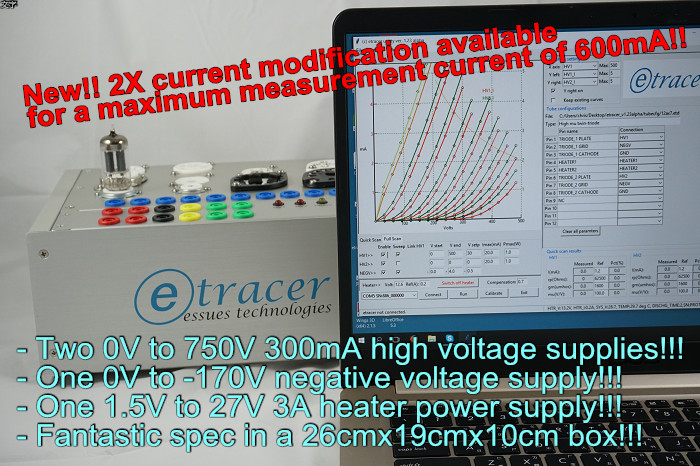

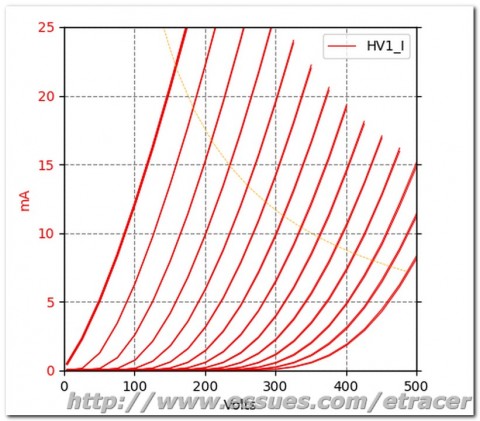

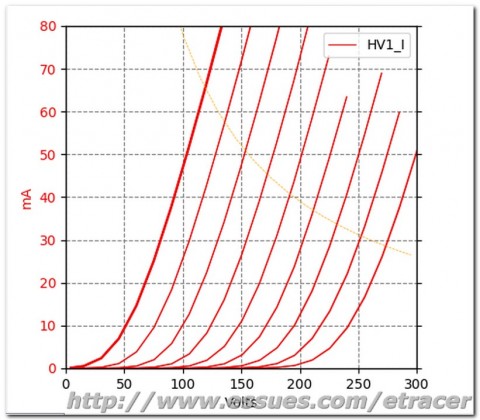

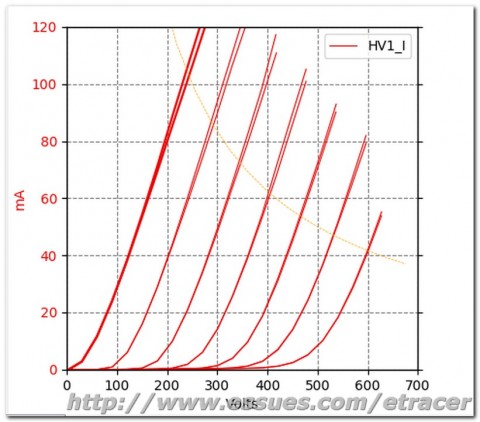

Now, let's investigate the fundamental question: what's the measurement deviation between a DUT with heater-powered only and a DUT under it's maximum plate dissipation? I conducted a test using the tubes on my 50 singled-ended power amplifier. There are a total of three tubes in the signal path of the amplifier: a 6C4, a 6C45 and a 50. Among the three tubes the 6C4 operates at about half of it maximum plate dissipation of 3.5W while the 6C45 and the 50 are biased close to their maximum plate dissipation. For each tube I conducted two curves-traces. One set of curves comes from the DUT being powered by etracer's heater supply for 10 minutes. One set of curves is from the DUT plugged in the amplifier for 1 hour and quickly removed from the amplifier and mounted on the etracer to take measurement. With the software version 2.x it is easy to display two sets of curves on the screen and the differences can be eyeballed easily. The following figures are the measurement results for the three tubes:

As you can see from the figures differences do exist. However, for the 6C4 and the 6C45 tubes the differences are actually very small and can be safely ignored. For the 50 tube the deviations become quite visible at the points above the maximum plate dissipation. Even for this case I think the result is very acceptable from my point of view.The variation is much less than the effect of a 5% heater voltage change. The reason for a larger variation in the 50 might be due to the fact that it is the globe type from the 30s. The internal structure of this type of tubes might be more susceptible to the temperature changes than the later ST types or miniature types. I don't have enough samples to make a concrete conclusion. If you own a tube amplifier and an etracer you are welcome to share your experiences with me and the readers.

Jac van de Walle of Emssion Labs indicates the deviation comes from the distances changes between the plate, the grid and the cathode and from the temperature differences in the plate and the cathode. Jac indicated a 5% deviation for a new tube and 10% for a dying tube are to be expected. I am not sure where Jac get these estimations. For me an error of 5% is very acceptable for vacuum tube applications. Jac's comments can be found in the following link:

Note to get a result similar to mine it is very important to allow the heater to heat-up completely. A minimum of 5 minutes is required. If the DUT is kept in storage for a long period of time please allow more time (30 minutes or an hour) for the heater to warm up. The reason is for these tubes there might be air inside the tube due to leakage in the sealing and the getter inside the tubes will be activated and capture the leaked air gradually when the heater is heated. For more information on this topic please refer to the excellent book "Getting the most out of vacuum tubes" written by Robert B. Tomer.

Please also note the result I got applies to etracer which has a regulated heater supply only. I had mixed experiences with the heater supply in utracer and it is highly recommended to use a regulated external heater supply if you are using an utracer to conduct the measurement campaign.