- Details

- Category: Blog

- Hits: 24426

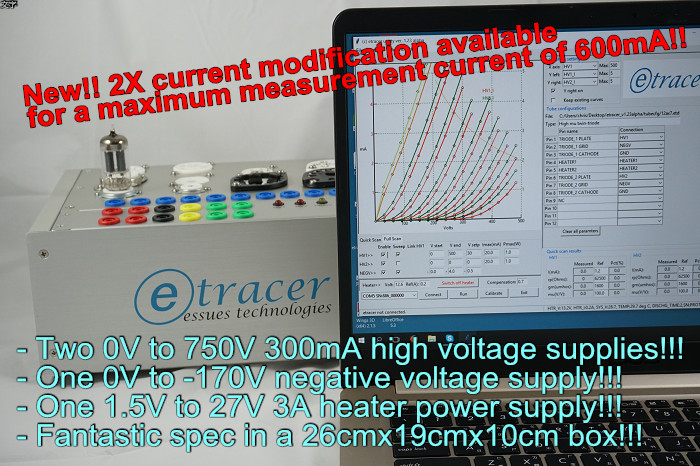

This site is dedicated to the development of etracer, the 'enhanced' vacuum tube curve tracer. This project was inspired by the utracer designed by Ronald Dekker (DOS4EVER). I purchased a utracer kit from Ronald in late 2015, assembled it and started to use it soon after. After using utracer for like two to three times I figured there are many things lacking in it. As a DHT (Directly Heated Triode) lover a lot portion of my vacuum tubes collections are power triodes like 2A3s, 300Bs and 50s. These DHTs need much more than -50V on the grid to give a complete curve scan. The maximum anode voltage of 400V on utracer seems to be adequate but for a complete curve scan I would like to go above 600V. Also the filament supply on utracer supplying 'equivalent power' by chopping a 19V DC supply is a little bit scary when testing valuable tubes. Nonetheless, Ronald's website has a lot of valuable information on the design of utracer. I strongly recommend readers to visit his utracer website: http://www.dos4ever.com/uTracer3/uTracer3_pag0.html

I really like the nice and clean design of utracer hence I offered Ronald Dekker a proposal to collaborate and improve the utracer based on Ronald's design. Unfortunately Ronald didn't like my proposal and hence I decided to start from scratch.

The etracer project was kicked off in April 2017 and I built the first prototpye on a perfboard. The main goal of the prototype was a viability study going above 400V. Through intensive studies on the internet I figured a way to bring the test voltage well above 1kV. However, due to the limited components selection and real estate concern I decided to stop at 750V. For the negative supply I adopted the same capacitor-charging principle and made it adjustable from 0V to -160V. I also designed a simple DC-DC converter to supply a maximum of 3A current from 1.25V to 26.5V for the filament.

The first etracer on a perfboard

The first etracer on a perfboard

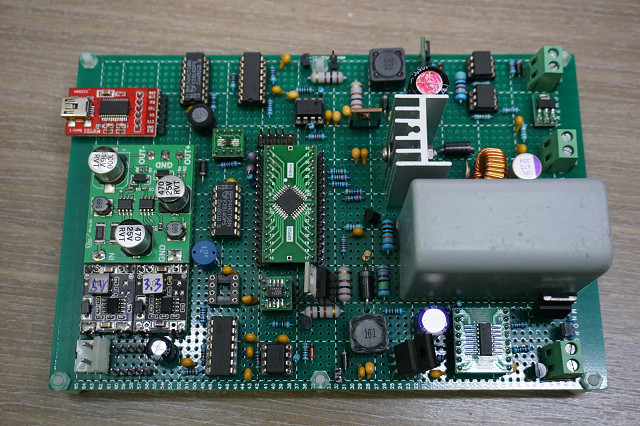

With the success of the perboard, I moved on and laid out a PCB using the open source software 'KiCad' and sent the Gerber files to a PCB manufacturer in China. The first PCB of etracer was received in June 2017 and was stuffed and verified within a week. The resulting product has an astonishing high voltage specification, a footprint of merely 21cm by 15cm. It is very power efficient due to the fact that it doesn't deliver current to the DUT (Device Under Test) during idle time. It can be powered by a DC source of 29V with a current specification over 3A. The components on the PCB draw less than 2 Watts during idle time. When the heater supply is turned on it will deliver power at specified voltage to the filament of the DUT with an conversion efficiency of at least 85%. When measurement starts the board will consume a maximum of 50 Watts more to charge the capacitors during a very short period of time.

Fully assembled etracer PCB V1.1

Read more: Introduction to the etracer vacuum tube curve tracer project

Page 3 of 3