click>>Check out our blog section for the latest features added to etracer!! <<click

Welcome to our website dedicated to etracer, a PC controlled vacuum tube curves tracer/tester.

Thanks to modern technologies such as switching mode power supply, high-voltage semi-conductor devices and high speed micro-controllers the amazing spec of etracer can be achieved efficiently. Unlike traditional vacuum tube testers, etracer uses short test pulses similar to a flash light in a camera system such that a capacitor is charged to a target voltage and then directed to the plate electrode of the vacuum tube under test during the measurement pulses.

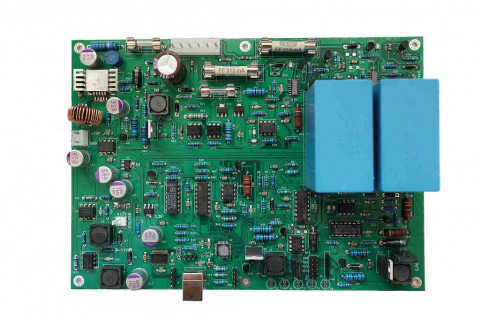

The heart of etracer contains two identical high voltage supplies named HV1 and HV2 respectively. HV1 is intended to be connected to the plate electrode of a TUT (tube under test). HV2 is connected to the screen electrode for a tetrode or pentode or connected to the plate electrode of the second unit for a twin-triode. A negative voltage supply of 0~-180VDC is implemented to supply the bias voltage for the grid electrode of the TUT. A 1.5V to 27V fully regulated DC power supply with a current capacity of 3A is available to supply vacuum tubes' heater up to 30 Watts. All the circuits are implemented in a 21cm by 15cm PCB (printed circuit board).

The etracer PCB is fully assembled and tested at our factory. The output voltage on each power supply is calibrated at 16 strategically spaced points. Adventurous users can purchase the bare etracer PCB and build a complete tester around it. For customers who want a turnkey solution the Model-01 chassis kit complete the etracer system in an extreme compact format of merely 26cmx19cmx10cm.

etracer with the Model-01 chassis

As vacuum tubes enthusiasts and vacuum tubes collectors etracer is designed the way we would like a vacuum tube tester to be. The high voltage supply must be high enough to test the vacuum tube at the maximum plate voltage. The negative voltage must be low (negative) enough to collect a full curves set for DHTs (directly-heated-triode). The spec for etracer is more than adequate to test common audio tubes ranging from small signal tubes such as 12AX7s and 6DJ8s to power tubes such as 300Bs and KT88s.

etracer can be used as a traditional vacuum tube testers with more parameters output such as quiecient current, transconductance (gm), amplification factor (u) and plate resistance (rp). For tetrode and pentodes the tube under test can be configured as a triode or as a tetrode/pentode. Twin-triode such as 12AX7 can be tested in one shot.

etracer is built to last with conservative parts selections and full protection circuits that prevents any short between it's 6 output pins.

The PC control software is written in Python with NumPy, SciPy and Matplotlib libraries. This software platform is independent of both underlying PC hardware and operating systems making it easy to adopt future OS evolution and always stays up to date.

The formal software releases provide three basic test modes: quick-scan, full-scan and corners-test. A combo-test mode is available to test a batch of tubes with a predefined heater warmup time. Measurement data can be saved in multiple formats such as text file, CSV file and PDF file. The traced curves can also be saved in jpeg or bmp format. When a full set of plate-curves are captured the basic-params mode displays the parameters of choice (current, gm, mu and rp) following the mouse cursor. And the cool load-line analysis tool allows the user to tweak the load-line and obtain the voltage swing, output power and distortion analysis up to the 7th order of harmonics on the fly.

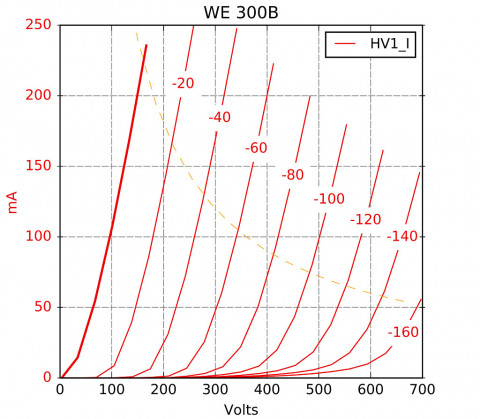

Sample traced curves for a Western Electric 300B triode

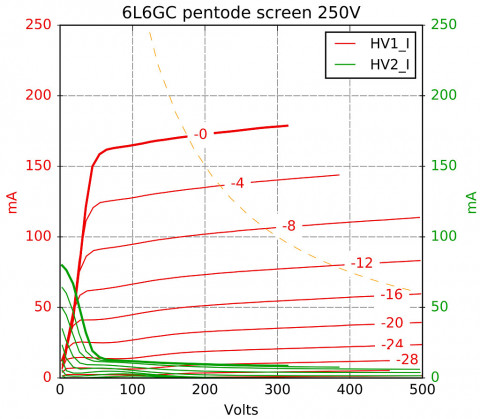

Sample traced curves for a 6L6GC under pentode connection with a screen volt of 250V

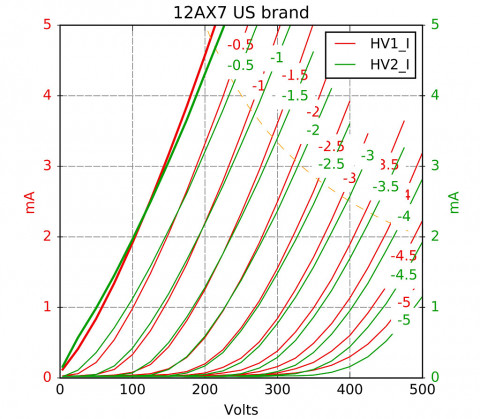

Sample traced curves for a 12AX7 twin-triode

The (trial) alpha version software comes with more features such as label-printing with a Brother QL series label printer, 2x current mode allows both high voltage supplies to supply up to 600mA (hardware modification required).

Since the introduction of etracer in late 2017 it is very well received by the tubes societies worldwide. Currently more than 500 sets of etracer were sold and our customers include repair-shop, musicians, tubes dealers and tubes collectors. Please check out the testimonials section for comments from our customers.

The following links provide deeper insights of the development and design philosophies for etracer. Be sure to check out our blog section for more articles.

-

Introduction to the etracer vacuum tube curve tracer project

-

The differences between etracer and utracer

-

The impact of working temperature to "pulse-type" vacuum tube testers

-

Why you need a tube tester that goes up to 750V?

-

Introduction to the PC control software version 2.xx

-

Hardware modification for increasing the maximum measurement current for etracer to 600 mA (2X)

-

Announcing the Sbox12- An automatic wiring box for etracer

-

Adding gas test to etracer

-

Considerations of components selection for etracer

-

New heater supply soft-start feature added to the etracer PC control software

-

Support for the Brother PT series label printers

We also have a video section with a collection of video clips that covers a variety of topics related to etracer and tubes testing.